The best packaging for your products and the environment

Customised packaging for your products

With THIMM packaging for a sales advantage

At THIMM you will find packaging solutions that can be adapted specifically to your requirements. Whether you need customised packaging for retail, specialist retail, catering or online shipping – THIMM knows the specific requirements and sets the highest quality standards. Our close collaboration with customers enables us to develop innovative packaging solutions that not only optimise protection, but also the presentation of your products. Have confidence in THIMM to meet your packaging requirements and secure a sales advantage: THIMM knows what is important in packaging!

Your advantages with sustainable corrugated cardboard packaging from THIMM

-

Variety of packaging types

Do you prefer standard or customised? THIMM has the appropriate packaging solution for every product.

-

100% recyclable

All corrugated cardboard packaging is fully recyclable – an ideal circular product.

-

Higher quality print images

Effective brand presentation thanks to state-of-the-art printing technologies with first-class print quality.

-

Extremely rigid

Corrugated cardboard packaging is lightweight yet sturdy.

-

Certified

We use certified materials.

-

Sustainable packaging

Corrugated cardboard consists entirely of renewable raw materials.

-

Consulting

Receive a personal consultation – we will find your best packaging.

-

Digital processes

Products can be tracked in coded packaging. This makes your goods flows transparent!

-

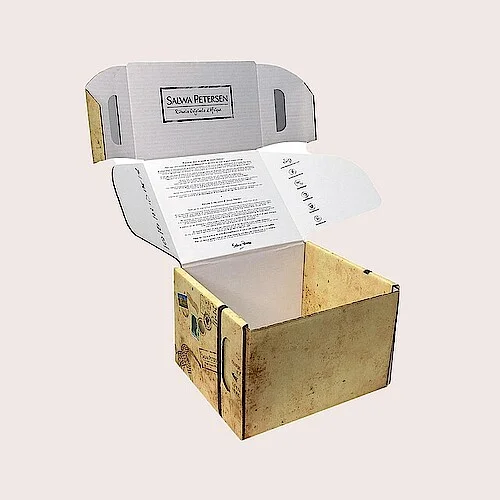

Customised internal printing

Very popular for personalised customer contact or as an advertising space for promotions.

Optimum packaging for successful projects.

Packaging made from corrugated cardboard The sustainable cycle

Corrugated cardboard packaging is environmentally friendly and consists mainly of recycled material. It offers high stability and can be recycled multiple times, making it an ideal cycle product. Corrugated cardboard can be recycled up to 20 times without compromising on quality. THIMM uses sustainable raw materials such as recycled paper and virgin fibres from responsible forestry when producing corrugated cardboard. Our corrugated cardboard packaging is an environmentally friendly alternative to plastics and offers excellent protection for various products.

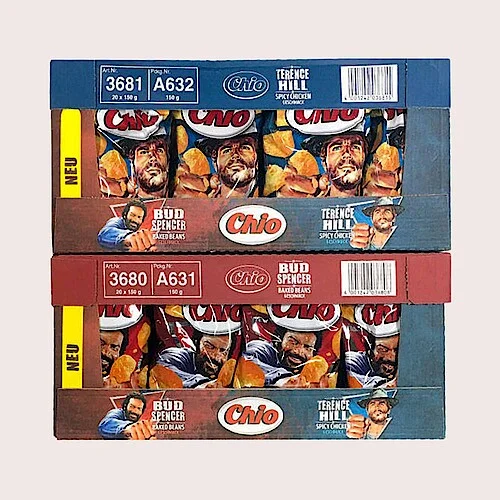

Retail packaging

Individual and innovative: THIMM is your packaging manufacturer

Retail packaging: Effective on the shelf

The presentation of your goods makes a crucial difference. With our POS packaging solutions, you raise the awareness of end consumers, noticeably stimulate purchases and also strengthen your brand.

Shipping boxes

Shipping boxes: sustainable and secure

Our resource-saving packaging made from corrugated cardboard is designed to package products safely and protect them from external influences. You pack your goods safely and in many different ways – to ensure they arrive intact at your customers and transform unpacking into an impressive experience. The easy handling and environmental aspects also reinforce the positive image of your delivered goods.

Food packaging

Packaging for all food products

Corrugated cardboard food packaging is designed to preserve the freshness and quality of your products. It forms a protective barrier against external influences. Whether your items are warm, fried, cold, frozen, unprocessed, heat-resistant, hot, microwave-heated or moist, eco-friendly corrugated cardboard packaging—made from recyclable paper—supports responsible material choices and appeals to environmentally conscious customers.

FEFCO packaging

FEFCO

The FEFCO-Code is a recognised system for classifying packaging made from solid and corrugated cardboard. There are nine different basic types – we will be happy to determine with you which are the best suited for packaging your products safely and attractively.

Intelligently shaping the future: Internet of Packs with THIMM

Packaging with codes and serial numbers makes your entire product journey traceable.

This is what we are often asked about packaging

Packaging types

In addition to food product packaging, retail packaging and shipping boxes THIMM also provides all FEFCO-types of packaging solutions. These packaging types can also be broken down into many sub-categories: For example, the retail packaging category includes product packaging, shelf-ready packaging, transport packaging, top-sleeve boxes and wrap-arounds. The FEFCO catalogue provides an ideal overview of all packaging types. All our products are made from corrugated cardboard.

Shipping bags, e-commerce packaging and folding boxes from THIMM are ideal for online shipping. They are made from sustainable, robust corrugated cardboard and therefore not only protect your product, but also the climate. Our shipping boxes can also be designed to be printed and customised in the best possible way.

Take advantage of our packaging optimisation and we will find innovative solutions together to significantly reduce your use of resources. We carry out a comprehensive analysis to identify all untapped potential and eliminate cost drivers.

With shelf-ready packaging (SRP) you can increase your retail efficiency through maximised visibility and an integrated and simplified packaging process. This packaging solution can be printed to create impactful advertising, yet still looks attractive even when the product unit is almost sold out. It also makes the packaging easier for consumers to remove.

At THIMM we are pursuing a clear digitalisation vision: We have committed to the Internet of Packs. The Internet of Packs describes fully networked and traceable supply chains for all products and this is made possible by digitally printed packaging.

Sustainability

Our corrugated cardboard packaging is ideally suited to the circular economy, as it is made from sustainable, natural raw materials and is fully recyclable. Overall, corrugated cardboard packaging is an ecologically responsible choice that focuses on both the environment and customer needs.

There is not yet any scientific evidence of the advantage of reusable over single-use packaging: Studies show that the use of reusable solutions is not generally ecologically beneficial. THIMM is a pioneer in sustainable packaging solutions made from renewable and recycled raw materials. Our corrugated cardboard packaging is an exemplary circular product with an unparalleled recycling rate. Therefore, we believe that fibre-based (disposable) packaging should be at least comparable to reusable solutions.

Corrugated cardboard

Corrugated cardboard is created by gluing flute and liner papers together into one or more layers depending on product type. We use our corrugator for this purpose. It heats the paper rolls, moistens them with water vapour and under pressure and heat “irons” the flute into the paper. Corrugated cardboard base paper is used as the basic raw material – in Germany it is predominantly made from recycled paper with a proportion of fresh fibres and starch glue.

There are different types of corrugated cardboard based on the number and type of flutes. In addition to single-sided corrugated cardboard, there is single-fluted corrugated cardboard made from three paper webs. For example, the B-flute is one such single-flute. Double-wall corrugated cardboard is referred to as double-fluted corrugated cardboard, e.g. EE-flute. Multi-fluted corrugated cardboard such as CAA-flute is also common.

Corrugated cardboard types and the associated paper grammages should be selected carefully and in accordance with the specific requirements of the products to be packaged as well as the transportation and storage conditions.

The flute types are differentiated by flute pitch (t) and flute height (h). The single-flute range includes the C-flute, also called central flute which is one of the most commonly used flute types for packaging. The flute height is between 3.1 and 3.9 mm.

The term solid board refers to all solid boards. They are mainly made of wastepaper. This means the structure of solid board is homogeneous and has a particularly high density. This makes it robust, but also significantly heavier. If you want to package high-quality products, we recommend our substitute for solid cardboard packaging: Our F-flute packaging.

Are you looking for the best packaging for your products?

THIMM Verpackung GmbH + Co. KG

+49 5551 703 0

hallo@thimm.de

We would be happy to advise you.

- Packaging for every requirement

- Fully recyclable corrugated cardboard packaging

- Effective brand presentation