Services

relating to packaging and displays

THIMM services – sustainable, safe and straightforward.

Our packaging and display services are the obvious solution for companies looking to save money and optimise their processes. We offer the opportunity to transport and present your products easily, safely and sustainably.

Our team is made up of experienced experts who support you every step of the way and provide you with tailored solutions. We believe our services will help you achieve your goals and take your business to the next level.

Choose our services and benefit from our expertise and experience. If you're looking to optimise your packaging and displays or simplify your processes, we're your go-to partner.

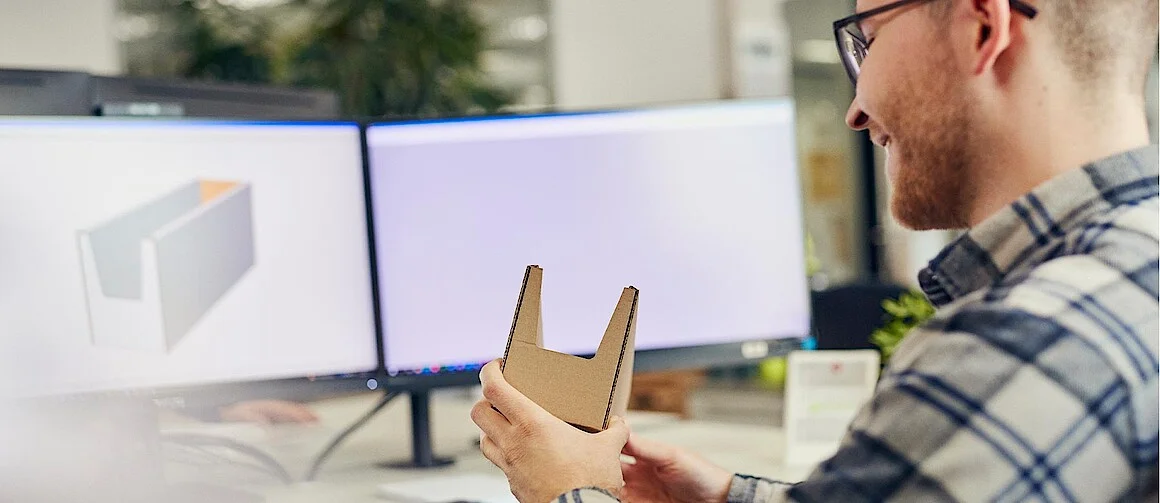

Packaging consulting

Efficient, sustainable, individually tailored advice.

Packaging optimisation by THIMM

Saves resources!

Packaging development

Customised solutions from THIMM

Calculating CO₂e

for packaging and displays

Electronic Data Interchange (EDI)

Simplifying processes

Augmented Reality

Experience packaging interactively

Do you have any questions about our services?

THIMM Group

+49 5551 703 0

info@thimm.de

Contact us today and let’s improve your packaging solutions together.

Still not found what you’re looking for?